I started this kirtle in 2014/2015 cutting it from the leftover yardage of the olive fitted gown and an old bodice block I drafted on newspaper. This kirtle differs from ones I’ve made before in that it has a very full skirt (possibly too full) and half sleeves.

Images from the Da Costa Book of Hours at the Morgan Library and Museum served as my main inspiration for the half sleeves. I did not try for the deep V back neckline, I have sloped shoulders and have had issues with the straps pulling if I go too low in the back.

The whole project lived in a large shoe box through two moves, getting taken out from time to time, worked on and then returned to the box.

This year I was determined to finish it. If only to make sure I wouldn’t misplace the half sleeves again.

I already sewed the skirt together, so that left me with the bodice to wrangle.

Building the Bodice

- Pad stitch interlinings by hand

- Flatline to bodice

- Cut bodice linings

- Baste bodice and try it on

- Adjust the bodice to fit and piece shoulder seams

- Sew the bodice

- Hand sew in the bodice lining

- Hand sew the eyelets in black silk twist

- Sew shoulder straps

- Test fit sleeves and cut the lining

- Sew sleeves

- Set the sleeves

- Bind the armscye

To piece the shoulder straps I made small lined rectangles and whip stitched them in by hand. I’ve done this a few times before, but I’m not fond of how bulky the area becomes with all the seam allowances building up in that small area.

The sleeve head is looking a little sad in the photos because I have mannequin arms stuffed and pinned onto a dressform they did not come with.

Once the bodice was together I attached the skirt by hand and folded over the bodice lining to hide the join. When I got ready to level out the skirt I realized in my excitement to get every bit of skirt out of the fabric I had I went a little overboard. I was looking at a 6 yard hem to level and bind.

Speaking of binding, I was down to a handful of scraps.

This became frankenbinding. Some strips were on the straight, some on the bias, the widths varied and once I had all the binding sewn on I was still 6 inches short. So I pulled some slightly darker wool from the stash and used that.

Once the hem was bound, pressed, steamed and clapped into submission I faced the cold hard reality that leaving my skirt unlined was a mistake. The wool I used for the kirtle is tropical suiting weight, this makes it very breathable and easy to wear but it does like to fray when cut along the straight. Now it was not fraying like some brocades do when you look at them, but it was enough that clipping the threads that worked their way lose would be bothersome.

So I hand sewed the seam allowances down in a bastardized stitch that is a mix of the prick stitch, the running stitch and the back stitch in black silk thread.

The final finishing was reinforcing the stress points along the kirtle with a very fine whip stitch at the corners of the bodice front and back and at the front skirt seam opening.

The Half Sleeves

The caramel wool over sleeves are a mixture of machine and hand sewing. I used my green half sleeves as a pattern and made them a little longer and a little roomier. All in all it is just a two part tapered rectangle. I sewed the wool and the linen lining up on the machine. Pressed. Matched the seams at the top and sewed the tubes together and turned them out. To finish hem off I bound the bottom edges in stripes of the wool and finished them by hand. I decided on the bottom edge as that is where these will get the most wear and tear over time and the binding is easy to replace.

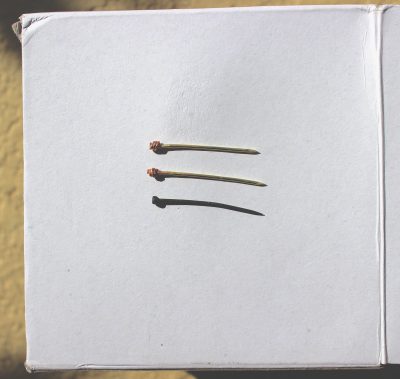

The sleeve pin on to the upper sleeve with my handmade brass pins.